Key features:

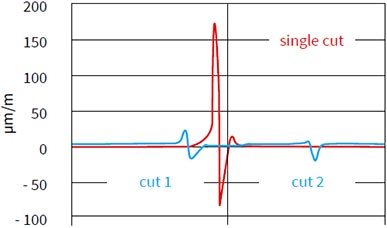

By traversing the milled groove once, tensile and compressive stresses can cause damage to sensitive components located close to the groove. A second traverse and simultaneous readjustment of the blade distance already reduces stresses considerably. The quality of the assembled PCBs improves significantly.

Material: FR4 1.5 mm

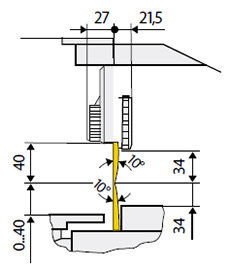

Residual thickness approx. 0.6 mm

Dial gauge

In order to separate without stress and to achieve a long service life, the circular and linear blades have to be guided along the entire separation. The dial gauge setting and regularly checking the parallelism is assembled to the carriage.

To separate aluminum with MAESTRO 4S, special adjustment is needed for the standard circular blade. For information see the operator's manual

Aluminum PCBs are manufactured in various alloys. Sample PCBs added to a request help with adjusting the circular blade and optimizing the cutting geometry.

Component height

Outside dimensions increased |  | |

The milled groove may be interrupted by cutouts. | ||

Protruding components need a recessed linear blade. |  | |

Specification

| Technical data | 4S/450 | 4S/600 |

|---|---|---|

| Separation method | Component side: Circular blade Solder side: Linear blade | |

| Operation | path-optimized, motor-driven | |

| Separation speed | 300, 500 mm/s, to be switched | |

| Materials | FR4, aluminum | |

| Component height | Component/solder side up to 34 mm | |

| Separation length | up to 450 mm | up to 600 mm |

| Support table depth | 200 mm | |

| Programming | ||

| Start | Traverse to initial position | |

| Programs | 9 | |

| Separation steps | 1 - 5 | |

| Blade distance | 0.9 mm - 0.05 mm | |

| Key switch button | Unlock program selection | |

| Performance display | up to 99 km | |

| DEL | Step reset | |

| Power switch | ON / OFF | |

| Foot switch | START separation | |

| Safety switch | E-stop | |

| Power supply | 100 - 240 VAC, 50/60 Hz | |

| Emission sound pressure level | LpA < 70 dB (A) | |

| Temperature/humidity: Operation Stock Transport | + 10 - 35°C / 10 - 85 % not condensing 0 - 60°C / 20 - 80 % not condensing – 25 - 60°C / 20 - 80 % not condensing | |

| Width x Height x Depth | 702 x 434 x 425 mm | 852 x 434 x 425 mm |

| Weight | 38 kg | 46 kg |

| Approvals | CE, FCC Class A | |

Options

to deposit separated PCBs individually and further transport them aside. The speed adapts to the size of the PCB. Incoming PCBs are detected by a light barrier and the belt stops.

| Technical data | 450 | 600 |

|---|---|---|

| Conveyor belt material | antistatic | |

| Direction of movement | to the right | |

| Belt speed | 5, 6, 7, 8, 9 m/min | |

| Light barrier | to be activated to stop the belt moving | |

| Vertical distance to the linear blade | 5 - 17 mm | |

| PCB depth | up to 200 mm | |

| Belt width | 170 mm | |

| Length | 1,200 mm | 1,350 mm |

| Power supply | 100 - 240 VAC, 50/60 Hz | |

| Temperature / humidity Operation Temperature / humidity Stock Temperature / humidity Transport | + 10 - 35°C / 10 - 85 % not condensing 0 - 60°C / 20 - 80 % not condensing – 25 - 60°C / 20 - 80 % not condensing | |

| Weight | 14 kg | |

| Approvals | CE, FCC Class A | |

Standard Station